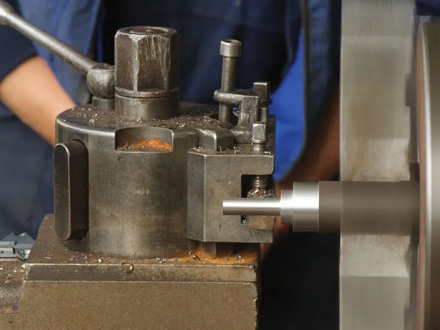

By turning the object on its axis, the lathe machine tool molds an object by cutting, sanding, drilling, or forming it. A lathe machine or Lathe Parts, in general, is used to shape workpieces and contains multiple components. The feed service lever, rear gear level, headstock, face plate, tool post, compound rest, saddle, clutch knob, and half nut lever are the most common. Every component of the machine is critical and performs extremely complex duties. The individual who works the equipment is referred to as a turner. It is entirely up to the expert turner to perform admirably, which necessitates a high level of concentration.

Lathe machines are used for a variety of purposes, including woodworking, metalworking, glassworking, metal spinning, decorative turning, shaping, rotational, and watchmaking. Each type of lathe has a distinct purpose. A steel workshop, for example, utilizes metal working lathes, whereas a carpentry workshop uses woodworking lathes. Various items and Turning Parts may be shaped with a lathe machine. Furthermore, a solid round bar can be formed into a bolt by creating a suitable thread. It can drill at precise angles by setting degrees and may be used for intricate drilling where it is difficult in a normal drilling machine.

Boring is another function of a lathe machine that is used to create holes within an item. It can easily carve a 6-inch hole using sharp instruments. Cutting tools and diamond cutting tools are the most often used tools for cutting solid materials. These two types of tools are used to refine a thing. The sharpening lathe item is an alloy that is made by adding some components to harden it. From 1300 B.C. until the present, the notion of lathing has evolved. During this period, it evolved for many roles, particularly in mechanical works, carpentry works, glass works, and steel fabrication, where its contribution was critical.

The primary components of the lathe are attached to the bed. It consists of the headstock, tailstock, carriage rails, and other components. The carriage, which is placed between the headstock and the tailstock, features an apron, saddle, compound rest, cross slide, and tool post. The Machining Parts are also vital.

By turning the object on its axis, the lathe machine tool molds an object by cutting, sanding, drilling, or forming it. A lathe machine or Lathe Parts, in general, is used to shape workpieces and contains multiple components. The feed service lever, rear gear level, headstock, face plate, tool post, compound rest, saddle, clutch knob, and half nut lever are the most common. Every component of the machine is critical and performs extremely complex duties. The individual who works the equipment is referred to as a turner. It is entirely up to the expert turner to perform admirably, which necessitates a high level of concentration.

Lathe machines are used for a variety of purposes, including woodworking, metalworking, glassworking, metal spinning, decorative turning, shaping, rotational, and watchmaking. Each type of lathe has a distinct purpose. A steel workshop, for example, utilizes metal working lathes, whereas a carpentry workshop uses woodworking lathes. Various items and Turning Parts may be shaped with a lathe machine. Furthermore, a solid round bar can be formed into a bolt by creating a suitable thread. It can drill at precise angles by setting degrees and may be used for intricate drilling where it is difficult in a normal drilling machine.

Boring is another function of a lathe machine that is used to create holes within an item. It can easily carve a 6-inch hole using sharp instruments. Cutting tools and diamond cutting tools are the most often used tools for cutting solid materials. These two types of tools are used to refine a thing. The sharpening lathe item is an alloy that is made by adding some components to harden it. From 1300 B.C. until the present, the notion of lathing has evolved. During this period, it evolved for many roles, particularly in mechanical works, carpentry works, glass works, and steel fabrication, where its contribution was critical.

The primary components of the lathe are attached to the bed. It consists of the headstock, tailstock, carriage rails, and other components. The carriage, which is placed between the headstock and the tailstock, features an apron, saddle, compound rest, cross slide, and tool post. The Machining Parts are also vital.

Get A Free Quote Now!

Your email address will not be published.